Carbon fiber car accessories are changing the game for auto enthusiasts looking to take their ride to the next level. With a blend of lightweight strength and eye-catching design, these accessories not only enhance performance but also elevate a car’s aesthetic appeal. From spoilers to dashboards, carbon fiber is becoming a popular choice in the automotive world, thanks to its impressive durability and stylish finish.

As we dive deeper, we’ll explore the benefits of using carbon fiber in automotive applications, the types of accessories available on the market, and why this material is gaining traction among car lovers. Whether you’re customizing a sports car or just looking to add a touch of class to your daily driver, understanding carbon fiber car accessories is key to making informed choices that suit your style and needs.

Overview of Carbon Fiber Car Accessories

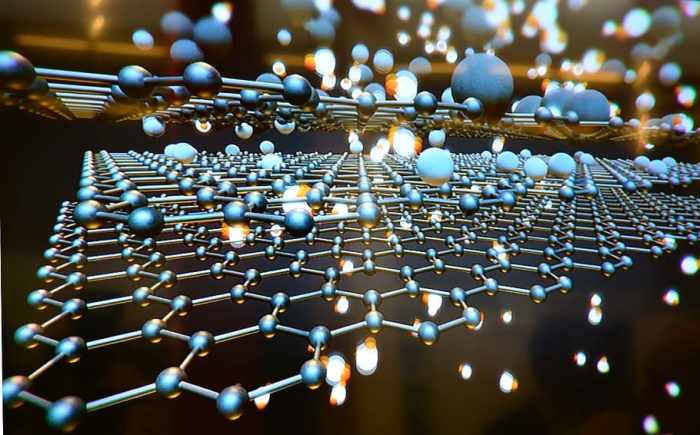

Carbon fiber has revolutionized the automotive industry with its lightweight yet durable properties, making it a popular choice for car accessories. The benefits of using carbon fiber in car accessories include improved performance, enhanced aesthetics, and greater fuel efficiency due to reduced weight. As a high-performance material, carbon fiber is characterized by high tensile strength, low density, and resistance to corrosion, which makes it particularly suitable for automotive applications. Common types of carbon fiber car accessories available in the market include hoods, roofs, spoilers, and interior trim pieces.

Benefits of Carbon Fiber

The advantages of carbon fiber extend beyond weight reduction. Its unique properties enhance the performance and longevity of automotive components. Key benefits include:

- Lightweight: Carbon fiber is significantly lighter than traditional materials like steel or aluminum.

- Strength: It boasts high tensile strength, making it strong and sturdy.

- Corrosion Resistance: Unlike metals, carbon fiber does not rust, ensuring durability.

- Design Versatility: Its ability to be molded into complex shapes allows for innovative designs.

Common Types of Carbon Fiber Car Accessories

Various carbon fiber accessories are now available, catering to car enthusiasts and manufacturers alike. Some popular options include:

- Carbon Fiber Hoods: Often found in performance cars, they reduce weight while adding a sporty look.

- Carbon Fiber Spoilers: Designed to improve aerodynamics and enhance vehicle stability.

- Carbon Fiber Dashboards: These add a modern touch to vehicle interiors.

- Carbon Fiber Trim: Used in various interior components for aesthetic enhancement.

Popular Carbon Fiber Car Accessories

The use of carbon fiber in car accessories is not just functional; it’s also about style. Many popular automotive models have embraced carbon fiber components for both performance and visual appeal.

Examples of Popular Accessories

Several accessories made from carbon fiber have become staples in the automotive world:

- Spoilers: Carbon fiber spoilers are favored for their lightweight nature and ability to create downforce.

- Dashboards: A carbon fiber dashboard provides a sleek, modern aesthetic that appeals to many drivers.

- Interior Trim: Carbon fiber trim offers luxury and customization options for various vehicles.

Car Models Utilizing Carbon Fiber Accessories

Luxury and performance cars frequently incorporate carbon fiber into their designs. For instance:

- Porsche 911: Known for its use of carbon fiber hoods and spoilers.

- BMW M Series: Features numerous carbon fiber components to enhance performance and style.

- McLaren Models: Heavily utilize carbon fiber for weight reduction and structural integrity.

Aesthetic Appeal of Carbon Fiber

The visual impact of carbon fiber is undeniable. Its unique weave pattern and glossy finish add a sporty and high-tech look to any vehicle. Car enthusiasts appreciate the customization options that carbon fiber provides, often integrating it into their cars for a distinct and personalized appearance.

Manufacturing Process of Carbon Fiber Accessories

Creating carbon fiber accessories involves a meticulous manufacturing process that ensures quality and performance.

Production Steps for Carbon Fiber Parts

The production of carbon fiber parts includes several key steps:

- Material Preparation: Raw materials are prepared, including carbon fiber strands and resin.

- Molding: The prepared materials are molded into the desired shape.

- Curing: The molded parts are cured using heat or pressure to achieve final hardness.

Technologies Used in Molding and Curing

Modern technology plays a significant role in the carbon fiber manufacturing process. Techniques include:

- Prepreg Molding: Using pre-impregnated resin systems for consistent quality.

- Autoclave Curing: Employing high pressure and temperature for optimal curing of parts.

- RTM (Resin Transfer Molding): Involves injecting resin into a mold containing dry carbon fiber.

Quality Control Measures

Ensuring the durability and performance of carbon fiber accessories is critical. Quality control measures include:

- Visual Inspections: Checking for surface defects or irregularities.

- Mechanical Testing: Conducting tests to verify strength and durability.

- Dimensional Checks: Ensuring parts meet specifications for proper fit and function.

Installation and Maintenance of Carbon Fiber Accessories

Proper installation and maintenance of carbon fiber accessories are essential for maximizing their lifespan and performance.

Guide to Installing Carbon Fiber Accessories

Safely installing carbon fiber accessories requires attention to detail. Key steps include:

- Preparation: Ensure all necessary tools and components are ready before starting.

- Fit Check: Test-fit the accessory to confirm compatibility.

- Secure Fastening: Use the correct fasteners and ensure everything is tightened properly.

Maintenance Tips for Longevity

To keep carbon fiber components in optimal condition, consider these maintenance tips:

- Regular Cleaning: Use mild soap and water to clean the surface; avoid harsh chemicals.

- Inspection: Periodically check for signs of wear or damage.

- Protective Coating: Apply a UV protectant to prevent fading and degradation.

Common Mistakes to Avoid

Avoiding certain pitfalls can greatly enhance the installation and upkeep of carbon fiber accessories:

- Over-tightening Fasteners: This can lead to cracking or damage.

- Neglecting Proper Cleaning: Accumulated dirt can degrade the material.

- Ignoring Manufacturer Instructions: Always follow guidelines for installation and maintenance.

Cost Analysis of Carbon Fiber Accessories

Understanding the costs associated with carbon fiber accessories is crucial for car enthusiasts and manufacturers.

Cost Comparison with Traditional Materials

When comparing carbon fiber accessories to traditional materials like plastic and metal, several factors come into play:

- Material Costs: Carbon fiber is generally more expensive due to its manufacturing process.

- Performance Gains: The advantages in weight savings and performance can justify the higher price.

- Longevity: Carbon fiber parts tend to have a longer lifespan, offering better value over time.

Factors Influencing Pricing

Several factors contribute to the pricing of carbon fiber accessories:

- Manufacturing Complexity: More complex shapes and designs can increase costs.

- Market Demand: Popular models and limited editions can drive prices higher.

- Brand Reputation: Established brands may charge a premium for their products.

Return on Investment Insights

Investing in carbon fiber accessories often yields significant returns in performance and resale value. Car enthusiasts can see higher resale prices for vehicles equipped with premium carbon fiber parts, making the initial investment worthwhile.

Environmental Impact of Carbon Fiber Production

The production of carbon fiber raises important environmental considerations that must be addressed.

Environmental Considerations in Production

The carbon fiber manufacturing process can be resource-intensive. Key considerations include:

- Energy Use: High energy consumption during production contributes to carbon footprints.

- Raw Material Sourcing: Accessing and processing raw materials can have ecological impacts.

Recycling Options for Carbon Fiber Accessories, Carbon fiber car accessories

As the automotive industry evolves, recycling options for carbon fiber are becoming more viable. Potential methods include:

- Mechanical Recycling: Ground carbon fiber can be repurposed for other applications.

- Chemical Recycling: Processes that break down carbon fiber into its base constituents for reuse.

Sustainability Initiatives in the Automotive Industry

Many automotive manufacturers are adopting sustainability initiatives related to carbon fiber, such as:

- Developing Bio-based Carbon Fibers: Exploring alternative, renewable resources for production.

- Implementing Circular Economy Practices: Focusing on reducing waste and enhancing recycling efforts.

Future Trends in Carbon Fiber Car Accessories

The landscape of carbon fiber accessories is continuously evolving, with exciting trends on the horizon.

Upcoming Trends in Design and Application

The future of carbon fiber in the automotive industry is promising, with several trends emerging:

- Integration with Advanced Technologies: Combining carbon fiber with sensor technologies for smart vehicles.

- Customization Options: Increased demand for personalized designs using carbon fiber.

Innovations Enhancing Functionality

Innovations in carbon fiber production methods and applications are enhancing functionality. Examples include:

- 3D Printing: Enables more complex designs and faster prototyping of carbon fiber components.

- Smart Materials: Incorporating sensors into carbon fiber for real-time monitoring of vehicle performance.

Challenges Facing the Carbon Fiber Industry

Despite the advantages, the carbon fiber industry faces challenges that could impact its growth:

- Cost of Production: High production costs continue to be a barrier for widespread adoption.

- Market Competition: Competing materials may offer viable alternatives, affecting demand.

Final Review

In summary, carbon fiber car accessories offer a unique combination of performance enhancement and visual appeal, making them a smart choice for any car enthusiast. As the automotive industry continues to innovate, the use of carbon fiber is set to expand, bringing with it new trends and technologies that promise even greater customization options. By upgrading to these accessories, not only do you improve your vehicle’s aesthetics, but you also invest in longevity and sustainability—a win-win for both you and the environment.